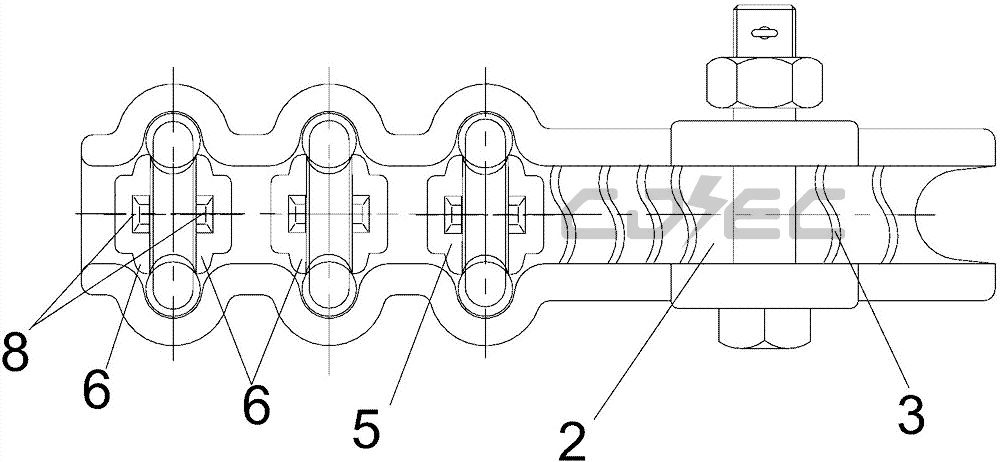

Bolt Type Aluminum Alloy Tension Clamp NLL-3

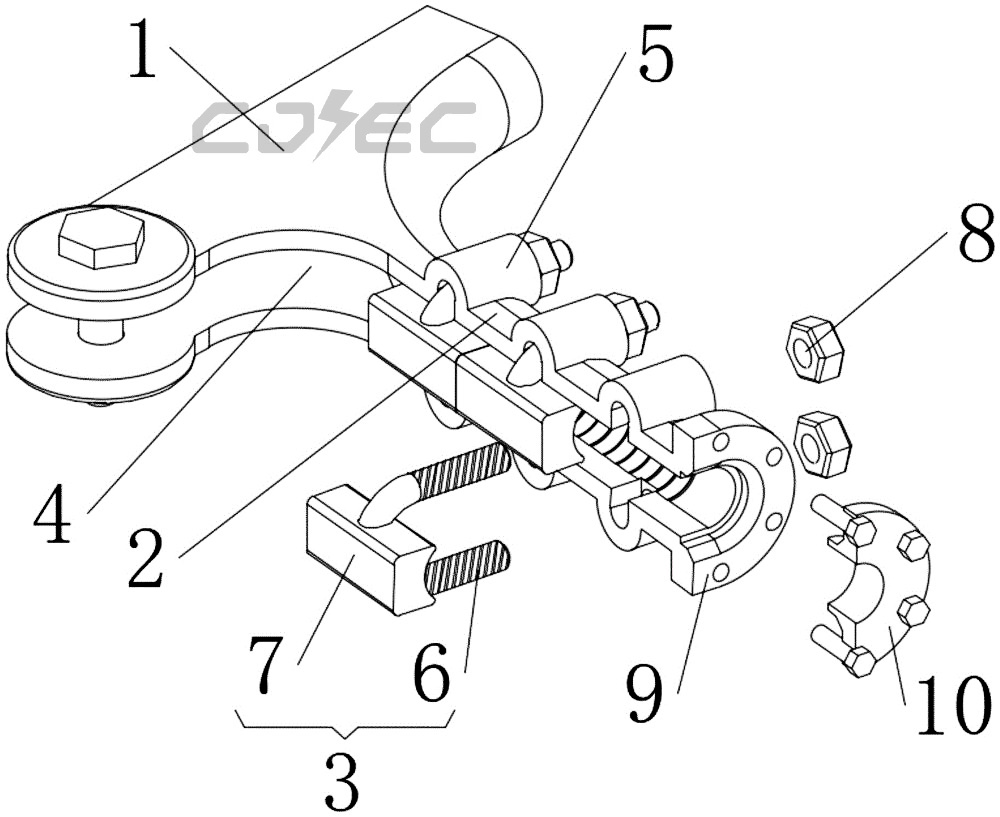

Drawing

Parameter table

| NLD Series Aluminium Alloy Tension Clamp | ||||||||||

| Basic Data | ||||||||||

| Type | Diameter of stranded wire | Dimensions (mm) | U bolt | Rated Failure Load(KN) | Cover used | Weight | ||||

| M | C | L1 | L2 | Nos | Dia.(mm) | (kg) | ||||

| NLL-1 | 5.0-10.0 | 16 | 19 | 140 | 120 | 2 | 10 | 40 | JNL-1 | 1.0 |

| NLL-2 | 10.1-14.0 | 16 | 24 | 176 | 187 | 2 | 12 | 40 | JNL-2 | 1.6 |

| NLL-3 | 14.1-18.0 | 16 | 18 | 310 | 160 | 3 | 12 | 70 | JNL-3 | 1.9 |

| NLL-4 | 18.1-23.0 | 16 | 30 | 298 | 284 | 3 | 12 | 90 | JNL-4 | 4.1 |

| NLL-5 | 23.1-29.0 | 22 | 36 | 446 | 342 | 5 | 12 | 120 | JNL-5 | 7.0 |

Advantages of strain clamp:

1. Effectively eliminate short circuit accidents caused by overlapping of small animals or foreign bodies;

2. Prevent electrical accidents caused by condensation flash soldering, pollution flash soldering and icicle sticking snow;

3. Prevent acid rain, salt mist and harmful chemical gas from corroding the incoming and outgoing lines of the transformer;

4. Avoid personal injury or death caused by pedestrians touching exposed electrical contacts by mistake;

5. The protective cover and metering device are fully closed to prevent criminals from stealing electricity;

6. Buckle structure, simple installation and reusable.

Product features:

1. The meanings of model letters and numbers in the table are: n represents tension clamp, l represents bolt type, l represents aluminum alloy, and numbers represent product serial number;

2. The body and pressing block are aluminum alloy, which has energy-saving effect. The closed pin is made of stainless steel, and the rest are hot-dip galvanized steel;

3. The grip force of the clamp shall not be less than 95% of the calculated breaking force of the conductor;

4. Add a bushing in the iron pin hole to become a tension clamp;

5. The surface color is uniform, the color is consistent, and there are no bubbles;

6. The section shall be uniform, free of bending and burr, and the surface shall be flat and smooth without bulge and sharp angle;

7. Strictly implement relevant international technical standards.

"1、 Different applicable places

1. Nll-2 strain clamp: applicable to 10kV and below overhead lines.

2. Nld-2 strain clamp: used for corner, connection and terminal connection. Spiral aluminum clad steel wire has very strong tensile strength and no concentrated stress, which plays a role in protecting and assisting vibration reduction of optical cable.

2、 Different functions

1. Nll-2 tension clamp: fix aluminum stranded wire or steel core aluminum stranded wire on the tension rod. When it is used for overhead insulated aluminum conductor, it is used together with the insulating cover for insulation protection.

2. Nld-2 tension clamp: it is used to fix the conductor or lightning wire on the tension insulator string of non-linear pole and tower for anchoring. It is also used to fix the stay wire of stay wire pole and tower.

3、 Different characteristics

1. Nll-2 strain clamp: the clamp body is made of high-strength aluminum alloy, with smooth appearance, long service life, convenient installation and use and no power loss. It is an energy-saving certified product.

2. Nld-2 tension clamp: Tension pre twisted wire and supporting connecting fittings. The grip strength of the clamp shall not be less than 95% of the rated tensile strength of the optical cable, which is convenient and fast to install and reduces the construction cost. It is applicable to ADSS optical cable lines with span ≤ 100m and line angle < 25 °."