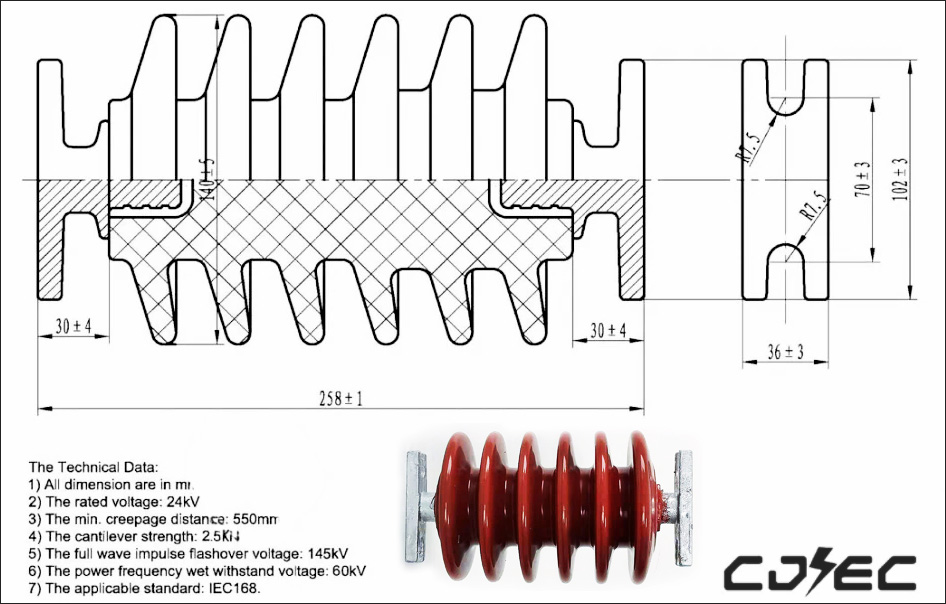

RTV Silicone Post Insulator P-70 Coating Red Epoxy Resin

Product Design Drawings

Product technical parameters

| Post Porcelain Insulator for Switch Gear | ||||

| Type | P-13 | P-70 | P-80 | |

| Dimension | ||||

| Diameter(D) | mm | 160 | 140 | 113 |

| High(H) | mm | 380 | 254 | 310 |

| Leakage distance (Creepage distance) | mm | 1000 | 500 | 400 |

| Mechanical Values | ||||

| Cantilever strength | kn | 2.3 | 3.6 | 2.7 |

| Electric Values | ||||

| Rated voltage | kv | 33 | 22 | 24 |

| Full wave impulse flashover oltage | kv | 230 | 140 | 145 |

| Wet power frequency flasho er voltage | kv | 95 | 70 | 70 |

| Packing and Shipping Date | ||||

| Net weight | kg | 9.6 | 6.2 | 4.8 |

The production process

Spray red epoxy silicone coating on the surface of the finished disconnector switch post isolator

We can spray RTV on the surface of any ceramic insulator.

As long as customers need it, we can develop it

Product advantages

The new composite silica gel insulator made of ceramic insulator sprayed with silica gel composite material on the surface can effectively use the narrow corridor for voltage switching and power transmission. It is suitable for the technical transformation of urban power grid, can reduce the height of tower, save a lot of manpower, material and financial resources, and has strong shockproof and impact resistance without manual cleaning, so as to provide guarantee for safe operation.

1. This product is suitable for dirty areas, high mechanical tensile load, large span and compact lines. The pollution flashover voltage is 30% - 50% higher than that of porcelain and glass insulators of the same grade. Stable performance at - 60 ℃ - + 200 ℃; The non breakdown design is adopted, and there is no need to measure the zero value during operation.

2. The silicone rubber umbrella skirt adopts the integral pressure injection process, which solves the key problem affecting the reliability of composite insulator, interface electrical breakdown. The most advanced crimping process is adopted for the connection between the glass pull-out rod and the fittings, and the automatic acoustic flaw detection system is equipped with high strength, beautiful appearance, small volume and light weight. The galvanized fittings can prevent rust and corrosion, and can be interchanged with porcelain insulators. The product has reliable structure, does not damage the core rod, and can give full play to its mechanical strength.

3. Superior electrical performance and high mechanical strength. The tensile and flexural strength of the epoxy glass pull-out rod loaded inside is 2 times higher than that of ordinary steel and 8 ~ 10 times higher than that of high-strength porcelain, which effectively improves the reliability of safe operation.

It has good pollution resistance, good pollution resistance and strong pollution flashover resistance. Its wet withstand voltage and pollution withstand voltage are 2 ~ 2.5 times that of porcelain insulators with the same creepage distance. Without cleaning, it can operate safely in heavily polluted areas.

4. Silica gel coating can effectively resist earthquake, collision and friction, and is convenient for transportation and installation.

5. The silicone rubber umbrella skirt has good hydrophobic performance. Its overall structure ensures that the internal insulation is not affected by moisture. There is no need for preventive insulation monitoring test and cleaning, which reduces the workload of daily maintenance.

6. It has good sealing performance and strong electric corrosion resistance. The material of umbrella skirt can resist electric leakage and scratch up to tma4.5 level. It has good aging resistance, corrosion resistance and low temperature resistance, and can be applied to - 40 ℃ ~ 50 ℃.

7. It has strong impact resistance and shockproof performance, good anti brittleness and creep resistance, not easy to break, high bending and torsional strength, can withstand internal pressure, strong explosion-proof force, and can be interchanged with porcelain and glass insulators.

8. Silica gel composite insulator series products have better mechanical and electrical properties than porcelain insulators and large operation safety margin. They are newer products for power lines.

Packaging