Characteristics of ceramic insulators

According to the application characteristics, electrical ceramic tubes can be divided into: Insulators for lines, insulators for power stations or electrical appliances; It can be divided into indoor insulator and outdoor insulator according to the application environment; Ceramic, natural clay as raw material, mixed material forming, workpiece Ordinary ceramics are used for daily use, building sanitation, electrical appliances (insulation), chemical industry and special ceramics – capacitors, piezoelectric, magnetic, electro-optic and high temperature electrical ceramics are usually classified according to the product shape, voltage level and application environment of electric ceramics. According to the product shape, it can be divided into: disc suspension insulator, pin insulator, rod insulator, hollow insulator, etc; According to the voltage level, it can be divided into low-voltage (AC 1000 V and below, DC 1500 V and below) insulators and high-voltage (AC 1000 V and above, DC 1500 V and above) insulators. Among the high-voltage insulators, there are ultra-high voltage (AC 330kV and 500 kV, DC 500 kV) and ultra-high voltage (AC 750kV and 1000 kV, DC 800 kV).

A kind of functional ceramics whose resistivity changes significantly with temperature. According to the resistance temperature characteristics, it is divided into positive temperature coefficient (PTC) Thermal Ceramics and negative temperature coefficient (NTC) Thermal Ceramics.

The resistivity of Thermal Ceramics with positive temperature coefficient decreases exponentially with the increase of temperature. This characteristic is required by the electrical properties of grains and grain boundaries in the structure of ceramics. Only ceramics with fully semiconducted grains and necessary insulation at grain boundaries can have this characteristic. The commonly used positive temperature coefficient thermosensitive ceramics are semiconducting BaTiO ceramics containing supporting impurities and workpieces in reduced atmosphere. They are mainly used to make power type swing variable thermosensitive ceramic resistors, current limiters, etc.

The resistivity of negative temperature coefficient thermosensitive ceramics increases exponentially with the increase of temperature. Most of these ceramics are transitional metal oxide solid solutions with spinel structure, that is, most oxides containing one or more transitional metals (such as Mn, Cu, Ni, Fe, etc.). The general chemical formula is AB2O4, and its conductive mechanism varies according to the composition, structure and semiconductor mode. Negative temperature coefficient thermal ceramics are mainly used for temperature measurement and temperature compensation. In addition, there are thermal ceramics whose resistivity changes linearly with the increase of temperature, and Thermal Ceramics whose resistivity changes again at a certain critical temperature. The latter is used to produce power supply devices, so it is called power supply Thermal Ceramics. According to the temperature range, thermal ceramics are divided into low temperature (4 ~ 20K, 20 ~ 80K, 77 ~ 300K, etc.), medium temperature (also known as standardization, – 60 ~ 300 ℃) and high temperature (300 ~ 1000℃ ).

Positive temperature coefficient thermistor; Semiconductor ceramics; Ferroelectric ceramics; development

Abstract: according to the literature reports and the experience in the work practice, the formulation research, process test, material characteristics and application of PTC ceramics are described.

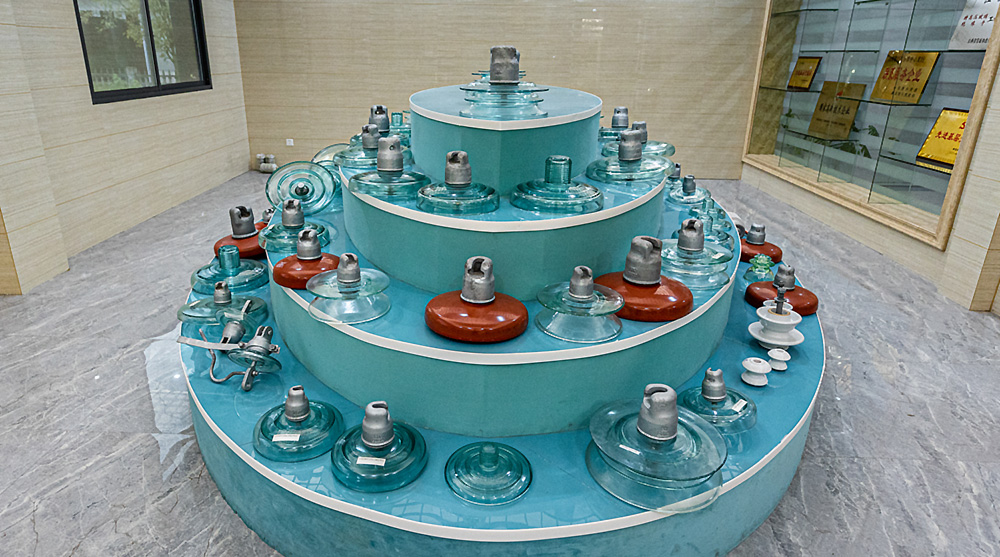

Johnson power, one-stop service for the world’s power users. Jiangxi Johnson Electric Co., Ltd. produces power insulators, porcelain insulators, glass insulators, composite insulators, line insulators, suspension insulators, pin insulators, disc insulators, tension insulators, lightning arresters, disconnectors, transformers, load switches, box substations, drop fuses, cables and power fittings. Welcome to inquire.

Characteristics of glass insulator

Glass insulator has the following characteristics:

(1) High mechanical strength, 1 ~ 2 times higher than that of porcelain insulator.

(2) The performance is stable and not easy to aging, and the electrical performance is higher than that of porcelain insulator.

(3) The production process is less, the production cycle is short, it is convenient for mechanized and automatic production, and the production efficiency is high

(4) Due to the transparency of glass insulator, it is easy to find small cracks and various internal defects or damages during external inspection.

(5) If there are various defects in the glass body of the insulator, the glass will automatically break, which is called “self breaking”. After the insulator is broken, the residual hammer of the iron cap still maintains a certain mechanical strength and is hung on the line, and the line can still continue to operate. When the line inspector inspects the line, it is easy to find the self broken insulator and replace the new insulator in time. Because the glass insulator has the characteristics of “self breaking”, it is not necessary to carry out preventive test on the insulator in the process of line operation, which brings great convenience to the operation.

(6) Glass insulators are light in weight. Due to the manufacturing process and other reasons, the “self breaking” rate of glass insulator is high, which is the fatal disadvantage of glass insulator

Type of composite suspension insulator:

standard type, pollution resistant type, DC type, spherical type, aerodynamic type, ground wire type, for overhead contact system of electrified railway.

1. The composite insulator product is composed of three parts: glass fiber epoxy resin pull-out rod, silicone rubber umbrella skirt and hardware. The silicone rubber umbrella skirt adopts the integral pressure injection process, which solves the key problem affecting the reliability of composite insulator, interface electrical breakdown. The most advanced crimping process is adopted for the connection between the glass pull-out rod and the fittings, which is equipped with a full-automatic acoustic flaw detection system. It has high strength, beautiful appearance, small volume and light weight. The galvanized fittings can prevent rust and corrosion, and can be interchanged with porcelain insulators. The structure is reliable, does not damage the mandrel, and can give full play to its mechanical strength.

2. Superior electrical performance and high mechanical strength. The tensile and flexural strength of the epoxy glass pull-out rod loaded inside is 2 times higher than that of ordinary steel and 8 ~ 10 times higher than that of high-strength porcelain, which effectively improves the reliability of safe operation.

3. It has good pollution resistance, good pollution resistance and strong pollution flashover resistance. Its wet withstand voltage and pollution withstand voltage are 2 ~ 2.5 times that of porcelain insulators with the same creepage distance. Without cleaning, it can operate safely in heavily polluted areas.

4. Small volume, light weight (only 1 / 6 ~ 1 / 9 of the porcelain insulator of the same voltage grade), light structure and convenient transportation and installation.

5. The silicone rubber umbrella skirt has good hydrophobic performance. Its overall structure ensures that the internal insulation is not affected by moisture. There is no need for preventive insulation monitoring test and cleaning, which reduces the workload of daily maintenance.

6. It has good sealing performance and strong electric corrosion resistance. The umbrella skirt material is resistant to electric leakage and marks up to tma4 Level 5, with good aging resistance, corrosion resistance and low temperature resistance, which can be applied to the area of – 40 ℃ ~ – 50 ℃.

7. It has strong impact resistance and shock resistance, good anti brittleness and creep resistance, not easy to break, high bending and torsional strength, can withstand internal pressure, strong explosion-proof force, and can be interchanged with porcelain and glass insulators.

8. The mechanical and electrical properties of composite insulator series are better than those of porcelain insulator, with large operation safety margin. It is an updated product for power line.

Characteristics of composite insulator

1. The zero value is self breaking and easy to detect

The compound hanging edge has the characteristics of zero value self breaking. As long as it is observed on the ground or on the helicopter, there is no need to climb the pole to detect piece by piece, which reduces the labor intensity of workers.

With the introduction of products from the production line, the annual operation self breaking rate is 0.02-0.04%, which can save the maintenance cost of the line. Good arc and vibration resistance. In operation, the new surface of the glass insulator burned by lightning is still a smooth glass body and has a toughened internal stress protective layer. Therefore, it still maintains sufficient insulation energy and mechanical strength.

The galloping disaster caused by conductor icing has occurred many times on 500 kV line. The composite suspension insulator after conductor galloping has no attenuation in electromechanical performance.

2. Good self-cleaning performance and not easy to aging

According to the general reflection of the power department, the glass insulator is not easy to accumulate pollution and easy to clean, and the glass insulator running on the south line is washed clean after the rain.

Regularly sample the glass insulators on the lines in typical areas to measure the electromechanical performance after operation. The accumulated thousands of data show that the electromechanical performance of the glass insulators after 35 years of operation is basically consistent with that at the time of delivery, and there is no aging phenomenon.

The main capacity is large, the voltage distribution in the string is uniform, and the dielectric constant of the glass is 7-8, which makes the composite insulator have large main capacitance and uniform voltage distribution in the string, which is conducive to reducing the voltage borne by the insulator near the conductor side and grounding side, so as to reduce radio interference, reduce corona loss and prolong the service life of the glass insulator. The operation practice has proved this

Performance characteristics and service conditions of composite insulator # performance characteristics of composite insulator:

1. Small volume and light weight, which is about 1 / 5 ~ 1 / 9 of the same voltage grade porcelain insulator, which is convenient for transportation and installation.

2. Composite insulator has high mechanical strength, reliable structure, stable performance and large margin for safe operation, which provides guarantee for line and safe operation.

3. The composite insulator has superior electrical performance. The silicone rubber umbrella skirt has good hydrophobicity and mobility, good pollution resistance and strong anti pollution flashover ability. It can operate safely in heavily polluted areas without manual cleaning and can be free from zero value maintenance.

4. The composite insulator has the characteristics of acid and alkali resistance, heat aging resistance and electricity resistance, good sealing performance, and can ensure that its internal insulation is not affected by moisture.

5. The composite insulator has good brittleness resistance, strong shock resistance and no brittle fracture accident.

6. Composite insulators are replaceable and can be interchanged with porcelain insulators .

How to judge the quality of insulator?

a. Standard for qualified insulation resistance

(1) The insulation resistance of newly installed insulators shall be greater than or equal to 500m Ω.

(2) The insulation resistance of insulator during operation shall be greater than or equal to 300m Ω.

b. Judgment principle of insulator deterioration

(1) If the insulation resistance of insulator is less than 300m Ω and greater than 240m Ω, it can be judged as low value insulator.

(2) If the insulation resistance of insulator is less than 240m Ω, it can be judged as zero insulator.

This method is generally not used to test the insulation resistance of composite insulation.

Suspension insulators are widely used in power system. FRP suspension insulators have long service life and are favored by power system. The quality of suspension insulators in the market is uneven. There are recycled waste suspension insulators on sale. It is necessary to compare the goods when purchasing suspension insulators. If you want to know about suspension insulator assembly and obtain suspension insulator connection pictures, you are welcome to consult Joson power equipment company, a manufacturer of high-quality suspension insulator. Josen power provides high-voltage electric porcelain suspension insulators, 330kV suspension insulators, 500kV suspension insulators, 10kV suspension composite insulators, suspension pollution resistant insulators, ordinary suspension insulators, disk suspension glass insulators and suspension ceramic insulators.

Post time: Apr-18-2022