1、 Self explosion mechanism of tempered glass

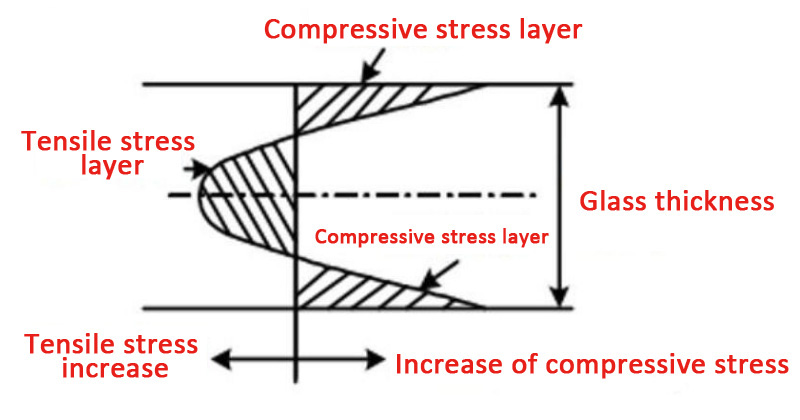

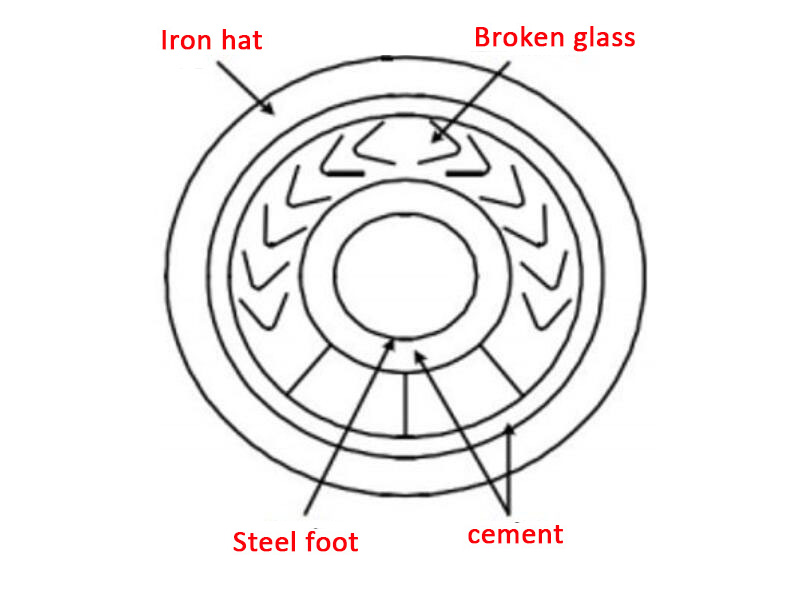

The glass insulator is tempered glass, which is characterized by compressive stress on the surface and tensile stress inside, as shown in the figure.

Stress stratification of tempered glass

The stress of glass is caused by the temperature change in glass processing. When the glass that has been heated to the softening temperature (760 ~ 780 ℃) cools rapidly, the quench force of the surface layer shrinks, but the internal temperature is still high and is in the expansion state, resulting in the obstruction of the shrinkage of the surface layer and the compressive stress in the surface layer; Then the internal temperature decreases and starts to shrink, but at this time, the surface layer has hardened, resulting in internal shrinkage obstruction and tensile stress. These two kinds of stresses are uniformly distributed in the glass until they are completely cooled and the temperature gradient disappears, which is permanent stress.

Once the balance between medium pressure stress and tensile stress of glass insulator glass is destroyed, cracks will occur rapidly under the action of stress, which will lead to the crushing of glass, that is, self explosion.

2、 Causes and characteristics of self explosion

The causes of glass insulator self explosion can be divided into two categories: product quality and external operating environment. In actual cases, there are often two reasons at the same time.

a. Reasons for product quality

The main reason is that there are impurity particles inside the glass insulator, and the most common is nis particles. The phase transition state of NIS in the process of glass melting and annealing is incomplete. After the insulator is put into operation, it is considered that the phase transition and expansion occur slowly, resulting in cracks in the glass. When the diameter of particle impurities is less than a certain value, it may not be removed by cold and hot shock, resulting in too high self explosion rate of insulators in operation [analysis of centralized self explosion of tempered glass insulators of 500kV transmission line Xie Hongping]. When the impurity particles are located in the internal tensile stress layer of the glass, the probability of self explosion is higher. Because the glass itself is a brittle material, which is resistant to pressure but not tensile, most of the breakage of the glass is caused by tensile stress.

characteristic:

A the self explosion caused by internal impurity particles is higher three years before operation, and will gradually decrease thereafter, which is an important law to judge the cause of self explosion.

B) the self explosion probability at different positions of insulator string is the same;

b. External causes

Mainly pollution and temperature difference change. Under the simultaneous action of pollution accumulation, moisture and electric field, the leakage current on the insulator surface is too large, resulting in part of the dry belt. When air breakdown occurs at the dry belt position, the generated arc will erode the glass umbrella skirt, and when the corrosion depth is deep, it will cause self explosion. If the insulator is struck by lightning during the above process, the self explosion probability of glass insulator that has been eroded by arc will increase significantly. Excessive fouling is the key, which may be due to too high salt density or too many metal powder particles in the fouling.

characteristic:

A) it is possible that the self explosion is not obvious in the first few years of operation, but occurs intensively at a certain time after several years of operation (major changes in local pollution sources cause excessive pollution accumulation);

B) the self explosion probability of the high-voltage end and low-voltage end of the insulator string is greater than that in the middle (the electric field at the high-voltage end and low-voltage end is strong, and local creepage occurs first at the steel foot of the insulator when the pollution is too heavy);

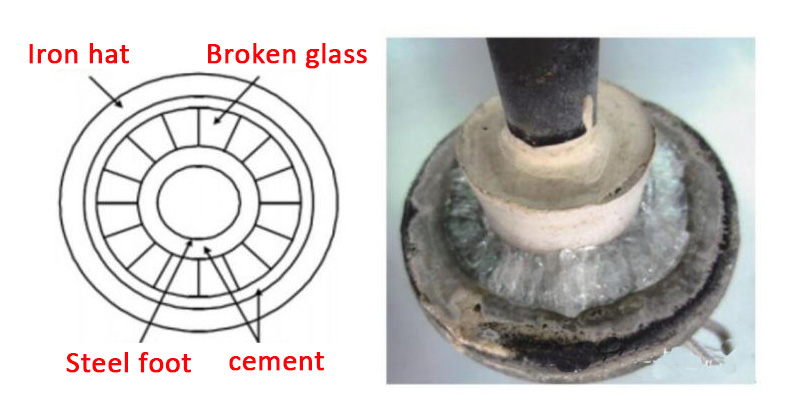

C) the steel leg of the non self exploding insulator in the same tower is damaged (local arc caused by excessive pollution accumulation causes damage to the glass near the steel leg), and there are fine cracks in the umbrella surface;

Glass damage near steel foot

3、 Residual hammer analysis

After the self explosion of tempered glass insulator, the umbrella disc glass is broken and scattered to form a residual hammer. The glass shape on the residual hammer can provide help for the analysis of the cause of self explosion. Shape and type of residual hammer glass:

a. Radial

For the self explosion caused by a single defect, the initiation point can be found by reverse searching the crack. If the broken glass slag on the residual hammer is in radioactive shape, its crack starting point, that is, the starting position of self explosion, is located at the head of the glass piece. In this case, the self explosion is caused by the quality of the glass piece itself, such as batching, dissolution process, etc.

Residual hammer radial

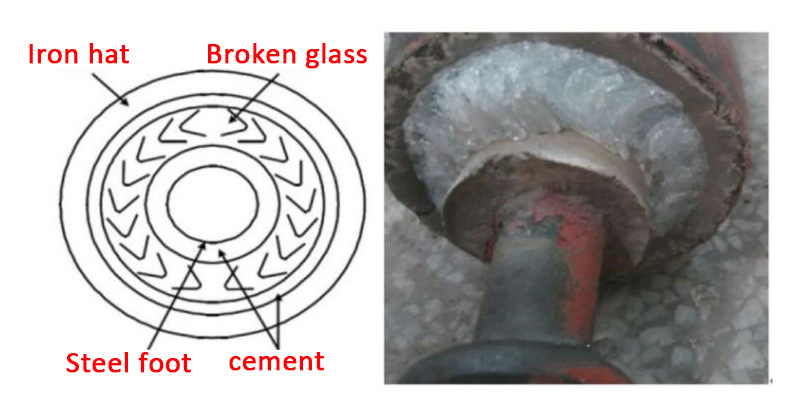

b. Fish scaly

If the broken glass slag on the residual hammer is in the shape of fish scales, and the starting position of self explosion is near the bottom of the glass part near the iron cap, there are two possible causes of self explosion in this case, that is, the glass is broken due to the self explosion of the product’s own defects or external force, which can be mechanical stress or electrical stress, such as continuous electric spark strike, the breakage of glass parts caused by power frequency large current and uneven leakage current, etc.

Residual hammer fish scale

c. Mixed

If the broken glass slag on the residual hammer exists in both fish scale and projective shape, the starting point of self explosion is located on the umbrella skirt of the glass piece. In this case, the self explosion may be caused by both internal and external factors.

Residual hammer mixed type

4、 Countermeasures

a. Access control: the quality of access glass insulators is controlled through sampling inspection of mechanical damage and steep wave impact performance.

b. Composite insulators are used in heavily polluted areas. If it is determined that centralized self explosion is caused by excessive pollution accumulation, composite insulators can be used to replace glass insulators.

c. Strengthen patrol inspection, and conduct special patrol on the transmission line in time after bad weather such as lightning strike.

d. Pay attention to transportation. During infrastructure construction and emergency repair, the tempered glass insulator shall be protected by protective articles to avoid damage.

At present, the quality control of glass insulators in large domestic manufacturers is good, and it is no longer necessary to use the glass insulators mentioned in the past after standing for half a year.

Post time: Apr-02-2022